Precise electrochemical metal machining (PECM for short) is a cold, contactless removal process with a vibrating electrode and controlled working gap, which enables the material to be dissolved in a targeted and controlled manner. This technology can be used to produce parts that require the highest precision and efficiency.

A pulsed direct current, which flows to the workpiece via the electrolyte, is applied between the electrode and the workpiece to be processed. The workpiece is anodically dissolved according to the geometry of the following electrode. The dissolved metal components are rinsed away by the flowing electrolyte.

This technology therefore enables the precise shaping of almost all metallic materials, regardless of their hardness.

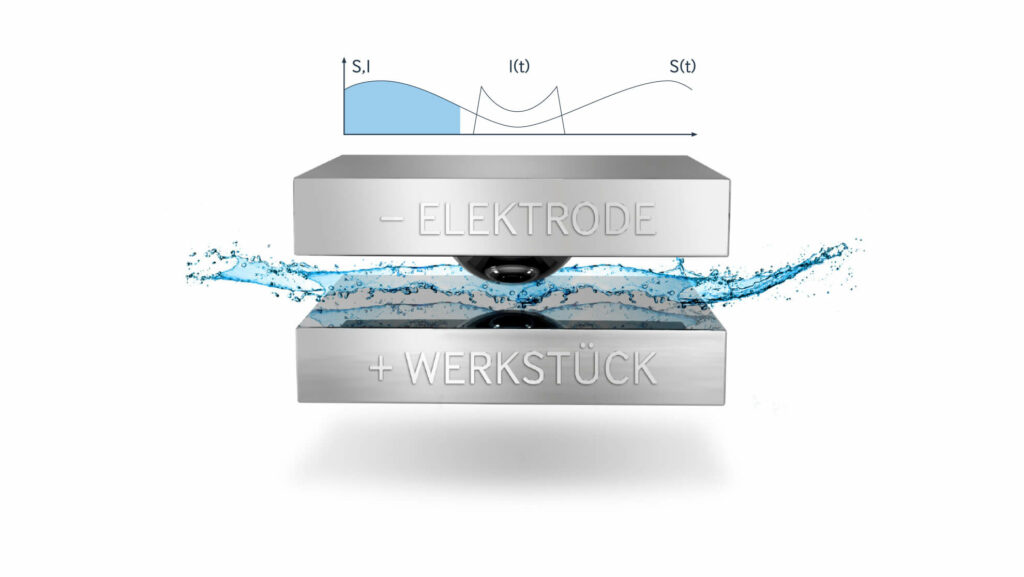

Step 1

Open the working gap; the fresh electrolyte is added.

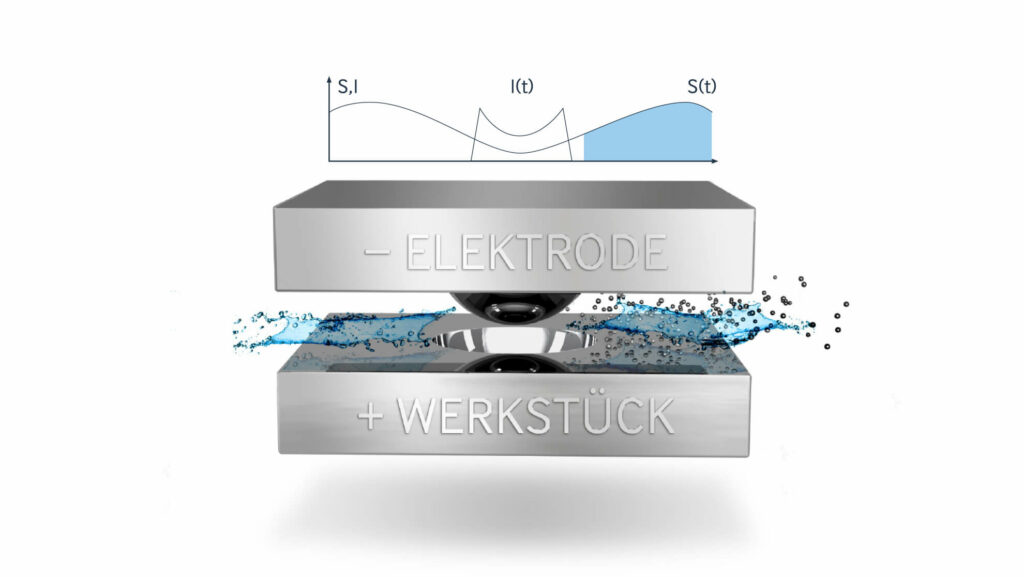

Step 2

Close the working gap. The tool electrode and workpiece approach each other to within a few microns. A controlled current pulse is triggered. At this moment, the surface of the material is anodically removed.

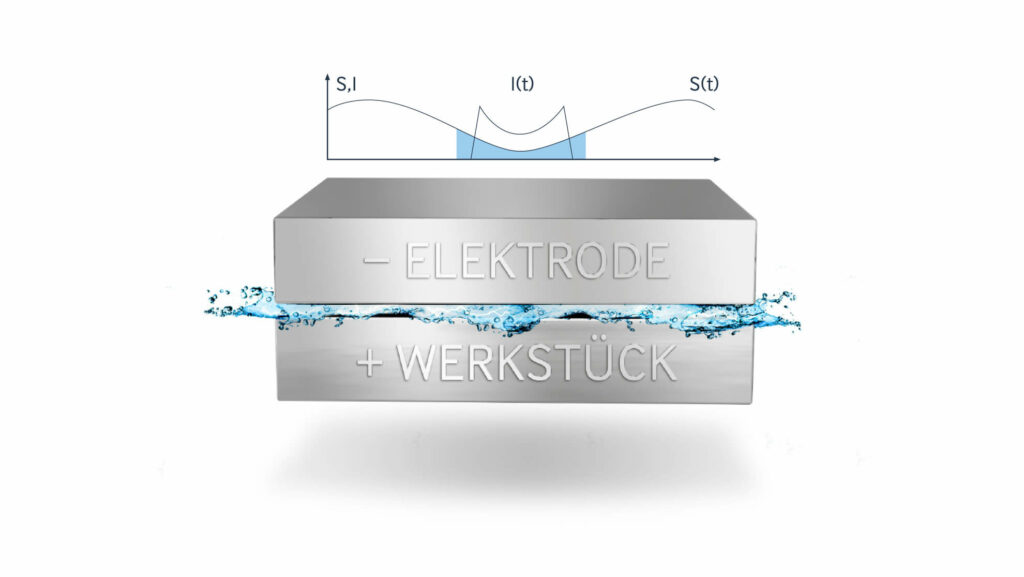

Step 3

Open the working gap. The electrolyte is rinsed out of the working gap with the removal products.